Li-Burrs ke bothata bo atileng tšebetsong ea litšepe, joalo ka ho cheka, ho phethola, ho sila le ho seha litšepe...

E 'ngoe ea likotsi tsa li-burrs ke hore li bonolo ho li khaola!Ho tlosa li-burrs, ts'ebetso ea bobeli e bitsoang deburring hangata e hlokahala.3 deburring le ho qetela ho qeta likarolo tse nepahetseng li ka ikarabella bakeng sa 30% ea litšenyehelo tsa karolo e phethiloeng.Hape, ho thata ho etsa mesebetsi ea bobeli ea ho qetela, kahoo li-burrs li fetoha bothata bo thata.

Mokhoa oa ho rarollaLITS'OANE

1 Ho tlosa chelete ka letsoho

Ena ke mokhoa o tloaelehileng le o sebelisoang ka tloaelo, ho sebelisa lifaele (lifaele tsa matsoho le lifaele tsa pneumatic), sandpaper, li-sanders tsa mabanta, lihlooho tsa ho sila, joalo-joalo e le lisebelisoa tse thusang.

Disadvantages: Litsenyehelo tsa basebetsi li theko e boima, katleho ha e phahame haholo, 'me ho thata ho tlosa likoti tse rarahaneng tsa sefapano.

Lintho tse sebetsang: Litlhoko tsa tekheniki bakeng sa basebetsi ha li phahame haholo, 'me li loketse li-castings tsa aluminium tse nang le li-burrs tse nyane le sebopeho se bonolo sa sehlahisoa.

2 Lefu la deburring

Deburring e etsoa ka ho sebelisa die ea tlhahiso le punch.

Go tlhoka mesola: E hloka palo e itseng ya die (rough die, fine die) ditjeho tsa tlhahiso, mme e ka boela ya hloka ho etsa dienywa tsa ho bopa.

Lintho tse sebetsang: E loketse li-castings tsa aluminium alloy die castings tse nang le libaka tse bonolo tsa karohano, 'me katleho le phello ea ho senya li molemo ho feta tsa mosebetsi oa matsoho.

3 Ho sila le ho bobola

Mofuta ona oa deburring o kenyelletsa ho sisinyeha, sandblasting, rollers, joalo-joalo, 'me hajoale e sebelisoa ke limela tse bolaeang.

Mefokolo: Ho na le bothata ba hore ho tlosa ha hoa hloeka haholo, 'me ka mor'a moo ho ka hlokahala hore ho sebetsanoe le li-burr tse setseng kapa mekhoa e meng ea ho tlosa.

Lintho tse sebetsang: tse loketseng bakeng sa li-castings tse nyenyane tsa aluminium tse nang le lihlopha tse kholo.

4 Ho qhoqhoa ha leqhoa

Sebelisa pholileng ho ebrittle burrs ka potlako, ebe o fafatsa projectiles ho tlosa burrs.Theko ea thepa e ka bang 200,000 kapa 300,000;

Lintho tse sebetsang: E loketse lisebelisoa tsa aluminium alloy die castings tse nang le botenya ba lerako le lenyenyane le molumo o monyane.

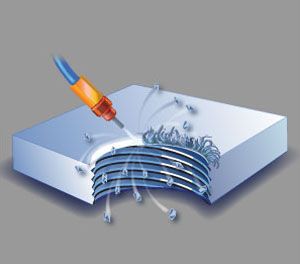

5 Ho phatloha ho chesang ho chesang

E boetse e bitsoa thermal deburring, explosion deburring.Ka ho hlahisa khase e 'ngoe e tukang ka sebōping sa lisebelisoa,' me joale ka ketso ea mecha ea litaba le maemo a mang, khase e phatloha hang-hang, 'me matla a hlahisoang ke ho phatloha a sebelisetsoa ho qhaqha le ho tlosa burr.

Mefokolo: lisebelisoa tse theko e boima (limilione tsa lidolara), litlhoko tse phahameng tsa tekheniki bakeng sa ts'ebetso, ts'ebetso e tlase, litlamorao (mafome, deformation);

Lintho tse sebetsang: E sebelisoa haholo libakeng tse ling tse nepahetseng haholo, joalo ka likoloi le likarolo tsa sebaka sa sefofane.

6 Deburring ea mochine o fatiloeng

Theko ea thepa ha e theko e boima haholo (mashome a likete).

Lintho tse sebetsang: E loketse mohaho o bonolo oa sebaka le boemo bo bonolo le bo tloaelehileng ba ho senya.

7 Ho tlosa lik'hemik'hale

U sebelisa molao-motheo oa karabelo ea electrochemical, likarolo tse entsoeng ka thepa ea tšepe li ka itokolla ka mokhoa o ikhethileng le ka mokhoa o ikhethileng.

Lintho tse sebetsang: tse loketseng li-burrs tse ka hare tse thata ho li tlosa, tse loketseng li-burrs tse nyenyane (botenya bo ka tlase ho lithapo tse 7) tsa lihlahisoa tse kang 'mele oa pompo le lihlopha tsa li-valve.

8 Ts'ebetso ea electrolytic

Mokhoa oa ho etsa mochini oa electrolytic oa ho tlosa li-burrs tsa alloy-casting ka electrolysis.Electrolytic deburring e loketse ho tlosa li-burrs likarolong tse patiloeng tsa aluminium alloy die castings, masoba a sefapano kapa likarolo tse nang le libopeho tse rarahaneng.Ts'ebetso ea tlhahiso e phahame, 'me nako ea ho senya hangata ke metsotsoana e seng mekae ho isa ho metsotsoana e mashome.

Go tlhoka mesola: Electrolyte e senya ho isa bohōleng bo itseng, 'me sebaka se haufi le sebaka sa burr sa likarolo le sona se tlas'a electrolysis, bokaholimo bo tla lahleheloa ke khanya ea eona ea pele, esita le ho ama ho nepahala ha dimensional.Aluminium alloy die-casting e lokela ho hloekisoa le ho thibela mafome ka mor'a ho senya.

Lintho tse sebetsang: E loketse ho thijoa ha likere, lithupa tse hokelang, 'mele oa li-valve le masoba a phasejeng a oli ea crankshaft, hammoho le ho pota-pota likhutlo tse bohale.

9 Ho tlosa jete ea metsi ka khatello e phahameng

E sebelisa metsi e le mokhoa oa ho sebelisa metsi, e ka sebelisa matla a eona a hang-hang ho tlosa li-burrs le mahlaseli a hlahisoang ka mor'a ho sebetsa, 'me ka nako e ts'oanang, e ka finyella morero oa ho hloekisa.

Cons: Thepa e turang

Lintho tse sebetsang: tse sebelisoang haholo pelong ea likoloi le litsamaiso tsa taolo ea hydraulic tsa mochini oa kaho.

10 Ultrasonic deburring

Ho sila ka mokhoa o tloaelehileng oa vibrate ho thata ho sebetsana le li-burrs tse kang masoba.Mokhoa o tloaelehileng oa ho phalla (abrasive flow machining process) o sututsa sekhopho ka har'a lisilindara tse peli tse nyahamisang tse shebaneng le ho etsa hore se phallele pele le morao ka har'a mocha o entsoeng ke workpiece le fixture.Ho kena le ho phalla ha abrasive ho kena le ho feta sebakeng leha e le sefe se thibetsoeng ho tla hlahisa phello e senyang.Khatello ea extrusion e laoloa ho 7-200bar (100-3000 psi), e loketseng lichapo tse fapaneng le linako tse fapaneng tsa potoloho.

Lintho tse sebetsang: E khona ho sebetsana le 0.35mm microporous burrs, ha ho na li-burrs tsa bobeli tse hlahisoang, 'me litšobotsi tsa mokelikeli li ka sebetsana le li-burrs tse rarahaneng.

11 Abrasive flow deburring

Ho sila ka mokhoa o tloaelehileng oa vibrate ho thata ho sebetsana le li-burrs tse kang masoba.Mokhoa o tloaelehileng oa ho phalla (abrasive flow machining process) o sututsa sekhopho ka har'a lisilindara tse peli tse nyahamisang tse shebaneng le ho etsa hore se phallele pele le morao ka har'a mocha o entsoeng ke workpiece le fixture.Ho kena le ho phalla ha abrasive ho kena le ho feta sebakeng leha e le sefe se thibetsoeng ho tla hlahisa phello e senyang.Khatello ea extrusion e laoloa ho 7-200bar (100-3000 psi), e loketseng lichapo tse fapaneng le linako tse fapaneng tsa potoloho.

Lintho tse sebetsang: E khona ho sebetsana le 0.35mm microporous burrs, ha ho na li-burrs tsa bobeli tse hlahisoang, 'me litšobotsi tsa mokelikeli li ka sebetsana le li-burrs tse rarahaneng.

12 Ho senyeha ha makenete

Ho sila ka matla a makenete ke hore tlas'a ts'ebetso ea matla a khoheli a matla a khoheli, li-abrasives tse tlatsitsoeng ka har'a matla a khoheli li hlophisoa ka tsela ea melapo ea matla a khoheli, li khabisitsoe holim'a lipalo tsa makenete hore li thehe "marusha a abrasive", 'me a hlahise khatello e itseng bokaholimo ba mosebetsi, 'me lipalo tsa makenete li khanna "abrasives".Ha borashe bo ntse bo potoloha, bo boloka lekhalo le itseng 'me le tsamaea holim'a sebaka sa mosebetsi, e le ho hlokomela ho phethoa ha bokaholimo ba mosebetsi.

Likarolo: theko e tlase, mefuta e mengata ea ts'ebetso, ts'ebetso e bonolo

Lintlha tsa ts'ebetso: grindstone, matla a matla a khoheli, lebelo la mosebetsi, joalo-joalo.

13 Setsi sa ho sila liroboto

Molao-motheo o ts'oana le ts'ebetso ea letsoho, ntle le hore matla a fetotsoe roboto.Ka tšehetso ea thekenoloji ea mananeo le thekenoloji ea ho laola matla, ho sila ho feto-fetohang (ho fetoha ha khatello le lebelo) hoa phethahala, 'me melemo ea ho senya liroboto e hlahella.

Ha li bapisoa le batho, liroboto li na le litšobotsi: ts'ebetso e ntlafetseng, boleng bo ntlafetseng le litšenyehelo tse phahameng

Li-Burrs Likarolong Tse Kgethehileng Tse Haliloeng

Likarolong tse haliloeng, ho qhekella ho thata haholo ebile ho theko e boima haholo, kaha li-burrs tse ngata li etsoa libakeng tse fapaneng tsa boholo bo fapaneng.Mona ke moo ho khetha liparamente tse nepahetseng tsa ts'ebetso ho fokotsa boholo ba burr ho bohlokoa le ho feta.

Nako ea poso: Sep-29-2022