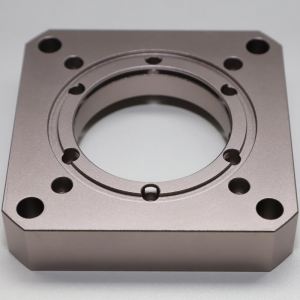

Likarolo tse entsoeng ka Aluminium e nepahetseng

CNC (Computer Numerical Control) machining ke mokhoa oa ho etsa subtractive: likarolo li etsoa ka ho tlosa thepa ho tloha ho thibela e tiileng (e bitsoang sekheo kapa se se nang letho) ho sebelisoa mefuta e sa tšoaneng ea li-cutters.

Ke mofuta o fapaneng haholo oa tlhahiso ho feta oa ho eketsa (khatiso ea 3D) kapa ho bopa (ho bopa ka ente).Mekhoa ea ho tlosa thepa e ama haholo matla a CNC, mefokolo, le meeli ea moralo.Bala haholoanyane ka tlase.

Ts'ebetso ea mantlha ea CNC e ka aroloa ka mehato e meraro.Rōna baenjiniere re qala ka ho qapa mohlala oa CAD oa karolo.Setsebi sa machini se fetolela faele ea CAD ho software ea CNC (G-code) ebe se theha mochini.Qetellong, sistimi ea machining ea CNC e etsa ntho e 'ngoe le e' ngoe ho tlosa thepa le ho etsa likarolo ka taolo e nyane.

Ka tlase ho na le liphekolo tse 'maloa tse tloaelehileng tse holimo tseo re li sebelisitseng lihlahisoa tsa rona, haeba u hloka tse ling ka kopo ikopanye le rona.Re tla hlahloba likopo tsa hau le maikutlo a hau ho uena.

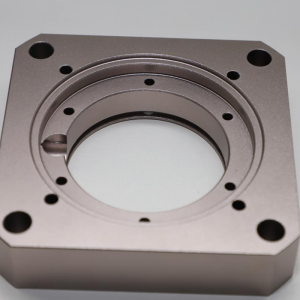

Anodizing: anodizing e atisa ho boleloa, ke mokhoa o fetolang holim'a tšepe e se nang ferrous hore e se ke ea senya, e khabisitsoeng, e se nang conductive oxide.Mefuta e fapaneng ea mebala e ka khethoa.

Ho benya:Ho pentša ke mokhoa oa ho theha bokaholimo bo boreleli le bo benyang ka ho bo tlotsa kapa ka ho sebelisa phekolo ea lik'hemik'hale, ho siea sebaka se hloekileng se nang le ponahalo e ikhethang.